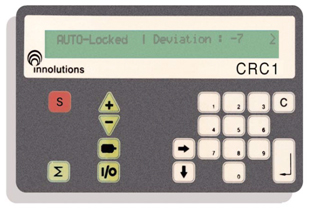

Features

Speed and Accuracy

A 12 bit Analog to Digital converter in SRC can sense the web movement as small as 0.001 inch. The system is rated at 3000 feet per minute.

Motorized Scanners

SRC's scanner automatically seeks the web. It can also

preposition the web at a programmed location or maintain

the web at an operator specified location.

Reduced Waste

With the faster response time, SRC handles splices and

tension upsets with significantly less waste than the

competition. Quality during normal production is also

improved with the help of built-in optimization through

statistical processing.

Customization

SRC is a true digital control. There are no potentiometers or set-up switches. All parameters are input digitally from the Operator Panel.

Statistical Quality Monitor

SRC eliminates subjective quality guesswork. The SQM feature gives you numeric values to compare the quality to the job specifications. This

information can be critical in troubleshooting and optimizing press parameters.

Splicer Feedback

SRC can interface with splicer control for automatically correcting roll setup errors.

Download the brochure

|